'Heritage' Double Glazed Units

Ravensby Glass is now manufacturing 'Heritage' sealed units (ultra thin double glazing).

The Heritage unit is a narrow sightline unit with an overall thickness of 12mm-16mm, manufactured specifically for historic and conservation sector. Due to their high specification they are suitable for:

- Listed properties

- Historic buildings

- Conservation Areas

- New builds

- Replacement & Refurbishment projects

The units are manufactured using a soft coat low emissivity glass with the lowest 'U' values available for the inner pane. We can produce heritage units incorporating panes of patterned, laminate, satin or clear glass.

All of the units are manufactured using Edgetech's warm edge 'Heritage' Super Spacer, which offers the ultimate in thermal performance and eliminates any possibility of cold bridge produced by traditional aluminium spacer bars. Additionally the 'Heritage' Super Spacer has a small up stand of only 3mm allowing us to offer an overall sightline of 7mm.

Technical Information

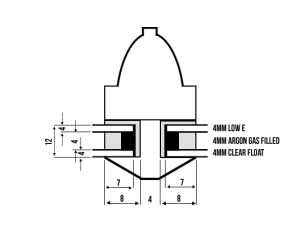

This is our thinnest heritage unit, with an overall thickness of 12mm and a 7mm sightline.

Minimum size is 150mm x 150mm Maximum size is 600mm x 600mm

Centre pane U value for unit incorporating 4mm Super Low 'E'- 4mm superspacer argon filled cavity- 4mm Clear Float= U Value of 2.5 W/m2K

Centre pane U value for unit incorporating 4mm Super Low 'E'- 4mm superspacer krypton filled cavity- 4mm Clear Float= U Value of 1.8 W/m2K

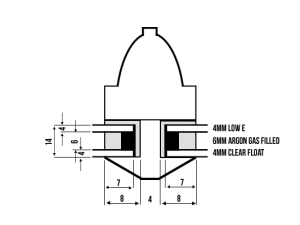

By increasing the overall thickness to 14mm with a 7mm sightline, we can achieve better U values.

Minimum size is 150mm x 150mm Maximum size is 750mm x 1000mm

Centre pane U value for unit incorporating 4mm Super Low 'E'- 6mm superspacer argon filled cavity- 4mm Clear Float= U Value of 2.0 W/m2K

Centre pane U value for unit incorporating 4mm Super Low 'E'- 6mm superspacer krypton filled cavity- 4mm Clear Float= U Value of 1.4 W/m2K

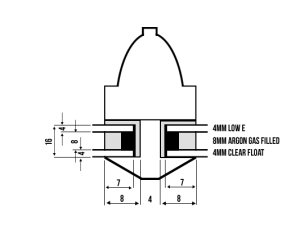

This is our thickest heritage unit, with an overall thickness of 16mm and a 7mm sightline.

Minimum size is 150mm x 150mm Maximum size is 750mm x 1200mm

Centre pane U value for unit incorporating 4mm Super Low 'E'- 8mm superspacer argon filled cavity- 4mm Clear Float= U Value of 1.6 W/m2K

Centre pane U value for unit incorporating 4mm Super Low 'E'- 8mm superspacer krypton filled cavity- 4mm Clear Float= U Value of 1.1 W/m2K

Glazing Guidelines

These glazing systems are suitable for the restoration of period properties, listed buildings and conservation areas. When cured, Heritage putty is elastic which results in more movement than traditional putties. This is beneficial for applications with a narrow sightline or narrow rebates.

glazing information

Glazing Information

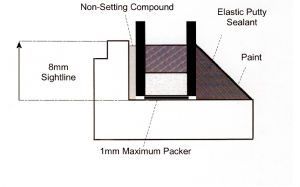

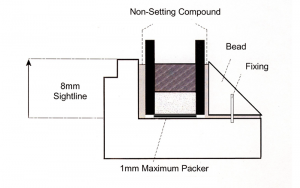

- Glazing details must be per diagram.

- Putty must be of elastic type

- Non setting compounds to be tapes or elastic sealant

- When painting windows ensure paint line is 2mm overlapping glass

- Minimum 1mm clearance required all round

- Bottom packers must always be used

Glass

Special soft coat low emissivity glass with the lowest 'U' values are available for the inner pane. The outer pane can be chosen from one of our many glass types including clear, patterned, laminate or satin.

measuring the frame opening

Measuring the frame opening

In order to allow the unit to be fully bedded in glazing material, each frame opening must be measured, the unit size calculated and the minimum required edge clearance taken into account as described below:

Calculating the size of reduced sightline units

According the the GGF, a reduced sightline unit is an IGU with cavity widths of 8mm or less and with reduced spacer bar sightlines. Typically these reduced sightline IGUs are required to have sightlines that are less than the usual minimum sightline depth, determined by the depth of spacer bar and the minimum sealant depth as stated by the sealant manufacturer.

In all instances it is recommended that the glazing method employed should be based on the IGU manufacturers own recommendations. Consideration will also need to be made when calculating the required size of the reduced sightline IGU.

Spacer Bars

Specifically designed for slim profile double glazing, Edgetech's warm edge 'Heritage' Super Spacer offers the ultimate in thermal performance and eliminates any possibility of cold bridge produced by traditional aluminium spacer bars. The 'Heritage' Super Spacer has a small upstand of only 3mm allowing us to offer an overall sightline of 7mm.

Gas

The most popular thermal insulation gases used in double glazing are Argon and Krypton. Krypton is a heavier gas and will offer improved 'U' values in narrower cavity units. The inclusion of Krypton gas allows us to offer 'U' values as low as 1.2 W/m2K.

Distance Pieces

Many instances of premature unit failure can be directly traced back to incorrect size selection or absence of distance pieces. Ideally they should have a thickness of 1mm.

Maintenance

Regular maintenance and repair is essential to ensure maximum performance of the glazing system and insulated glass unit.

Putty

Dryseal putty is paintable with water and solvent based products. It is recommended that a compatibility test is undertaken before use. Heritage putty can increase the drying time of solvent based paints therefore the use of a water based undercoat should be considered to avoid this. Skin formation and curing times of heritage putty will vary according to temperature and humidity, lower temperatures and humidity will extend the curing times. For best results it is recommended that paint is applied a few days after glazing. The paint should overlap the putty onto the glass by 2mm.

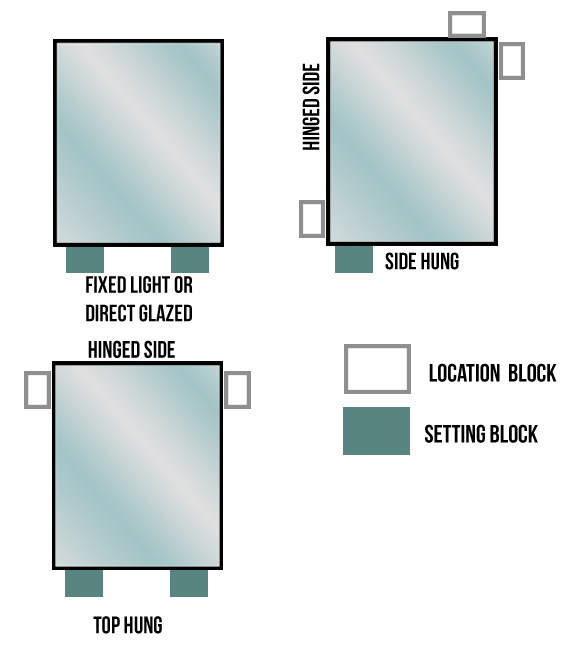

Glazing of Frames

1. All IG units must be positioned on setting blocks. If this window has an opening sash, each unit will need to have it's weight supported by location blocks in addition to the setting blocks. The position of setting and location blocks depends on which way the sash is hung. The diagram on the right explains the correct position of location and setting blocks.

2. Apply sufficient Dryseal Heritage Putty to the rebate and insert distance pieces .

3. Position the setting blocks on the bottom rebate as near quarter points as possible.

4. Position the bottom of the unit on the setting block(s). Using a glazing shovel inserted at the side of the unit to control and guide the unit, ease it back a little so that the unit can be centralised in the frame.

5. Press firmly all the way around the edge of the unit to engage the distance pieces soas to give a minimum 1mm thickness of compound.

6. If you are glazing an opening sash, insert location blocks around the sides and top of the units.

7. Apply further Dryseal heritage putty around the edge of the unit to completely fill the perimeter void.

8. Secure the IG unit using non-rusting metal sprigs.

9. Apply Dryseal Heritage putty to fill up the front bedding to the sightline. Kife/tool off the Dryseal Heritage putty to form a fillet that finishes level or fractionally above the sightline depending on painting requirements.

10. Tool off the back bedding of Dryseal Heritage putty before it forms a skin (<20 mins), finishing with a slope away from the glass.

Preparation of the sealed unit

Inspect the double glazed unit for obvious defects and wipe away any dust or loose material off the unit. Units should be stored in a clean dry area. Do not use chemicals or alchohol based cleaners on the edge seal.

1. Check that the moisture content of the window does not exceed 17%.

2. Remove all beads from the window.

3. Remove all dust, grease and loose material from the rebate. Any moisture on the timber should be wiped off using a clean paper towel or other absorbent material to give a dry surface.

4. Check the condition of any primer or stain on the frame, especially the rebate. Any section which has been partially missed or is considerably weathered should be reprimed or stained before glazing.

5. Check that the unit fits into the frame and can be centralised when standing the unit on the setting blocks. The spacer bar should ideally be level with the sightline or slightly below it.